CM OPM, Chocolate Bar Line, Model Nanoflex 275/205-15, With 2 Melt Tanks

Shipping Weight TBD

Shipping times will vary.

Limited International Delivery Available.

Product Description

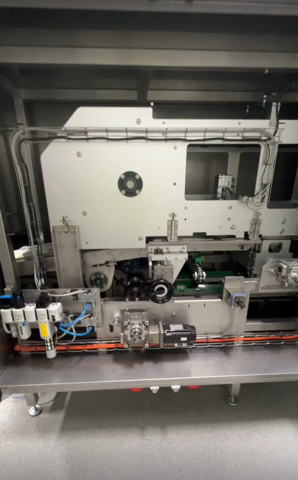

Type: Chocolate bar line

Model: Nanoflex 275/205-15

S/N: IPC16IM00009.3

Mfg Date: 2016

Capacity: 1322 lbs – 1543 lbs/Hr (600 – 700kg/Hr)

Produces Up To: 4500 Chocolate Bars Per Hour

Bar size range: 8″ x 8″ (205 mm x 205 mm)

Bar thickness range: .59″ – .78″ (15-20 mm)

Cooling tunnel length: 19.68′ (6 meters)

Dimensions: 30’W x 60’L x 12’H

Weight: 75,000 lbs.

Power requirements: 400 VAC, 50/60 Hz, 3 phase

Construction materials: Stainless steel

This Line Consists Of:

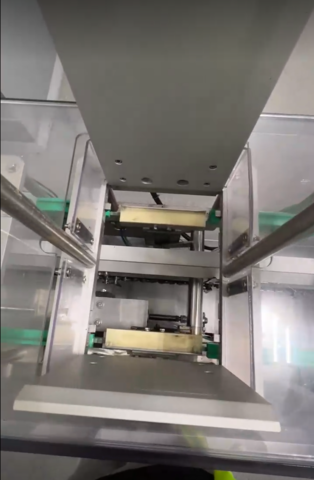

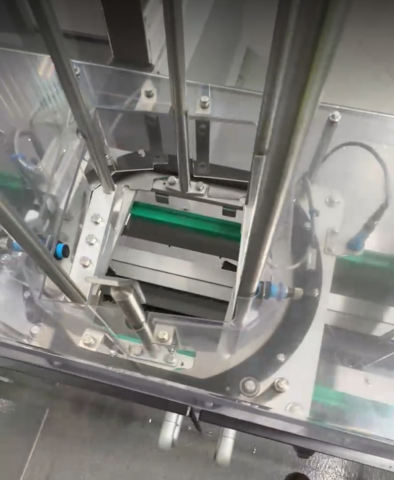

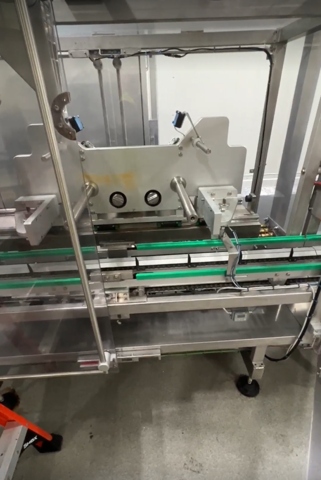

1) Depositor

1) Settling Shaker

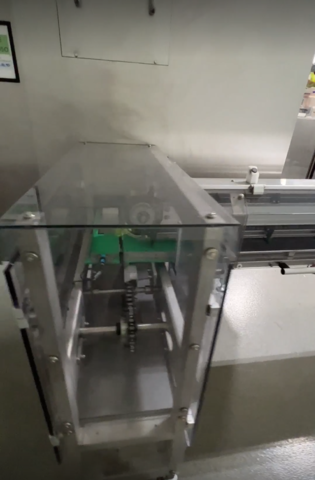

2) Cross Conveyors

1) Mold Tower Cooling Tunnel

1) Mold Overturn

1) Mold Vibrator

1) Mold Heater With Scraping Roller

1) Nester

1) Feed To Depositor (Continuous Mixer Over Depositor)

2) Jacketed Holding Tanks

1) 7 Door Control Panel

Inspection Station To Make Sure Mold Is Clean, If Mold Is Not Clean, It Is Rejected And A New Mold Is Inserted Via The Mold Magazine Hopper.

5500 lb Stainless Steel Jacketed Chocolate Tank. Water Jacketed And Agitated, Electronically Heated With Thermostat.

3 Hoppers:

1 Single Hopper: 18″W x 11-3/4″L (Crunch Die)

2 Dual Hoppers: 18-3/4″ x 11-3/4″ (Jacketed)

3 Pistons, 2 For Dual Hoppers And 1 For Single Hopper W/ 7/8″ Diameter Holes.

Piston Dimensions: 4.5″ x 18″

4 Depositing Plates:

Plate Dims: 4″W x 10-3/4″L x 5″H

Features:

-Compact design for small spaces

-High capacity for efficient production

-Wide range of bar size and thickness options

-Enrober with precise temperature control

-Cooling tunnel with variable speed control

-Easy-to-clean design

-Durable stainless steel construction

Applications

-Production of chocolate bars, slabs, and other molded chocolate products.

Benefits:

-High production capacity

-Wide range of product options

-Easy to operate and maintain

-Durable construction

Melt Tank 1:

Type Jacketed melt tank

Diameter: 60″

Capacity: 500 gallons

Jacket type: Steam or water

Temperature control: Yes

Dimensions: 6′ x 6′ x 10′

Rotan Transfer Pump

In-Line Filler Basket

4-Step Platform

Weigh: 1,500 lbs.

Construction material: Stainless steel

Features:

-Jacketed construction for precise temperature control

-Agitator for even product mixing

-Heating element for melting and maintaining product temperature

-Temperature control system for consistent product quality

-Durable stainless steel construction

Applications:

-Melting and holding chocolate, candy, and other confectionery products

-Melting and holding cheese, butter, and other dairy products

-Melting and holding soaps, detergents, and other personal care products

-Melting and holding industrial products, such as adhesives, sealants, and paints

Benefits:

-Precise temperature control for consistent product quality

-Even product mixing for a uniform product

-Durable construction for long service life

Melt Tank 2:

Features:

-Jacketed construction for precise temperature control

-Durable stainless steel construction

-Sanitary design for easy cleaning

-Temperature control system for consistent product quality

-Dimensions: 4′ x 8′ x 10′

-Weight: 1,200 lbs.

-2 HP Rotan Transfer Pump

Applications:

-Holding and maintaining chocolate, candy, and other confectionery products at a consistent temperature

-Holding and maintaining cheese, butter, and other dairy products at a consistent temperature

-Holding and maintaining soaps, detergents, and other personal care products at a consistent temperature

-Holding and maintaining industrial products, such as adhesives, sealants, and paints at a consistent temperature

Benefits:

-Precise temperature control for consistent product quality

-Durable construction for long service life

-Sanitary design for easy cleaning

-Even product mixing for a uniform product

Specifications

There are no specifications currently available for this product

Product Videos

Warranty

Warranty text

Related Products

Looking for financing?

Pay for this item monthly with financing from our partner Alliance Funding Group

Apply Now!