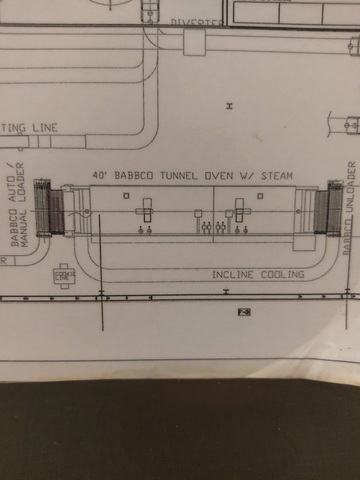

Babbco 2002′ Tunnel Oven With Turbulators, And Steam Section

Shipping Weight TBD

Shipping times will vary.

Limited International Delivery Available.

Product Description

This Oven Consist Of:

1) Babbco Pan Grouping Conveyor

1) Babbco Oven Loader And Unloader

1) Babbco Direct-Fired Tunnel Oven With Turbulators And Steam Section

DOM 2002′

Tube Burner Steam Section:

The Direct Fired Tunnel Oven Is Equipped With 45 Flynn Tube Burners (150,000btu’s each)

The Temperature In The Tube Fired Burner Zones Is Controlled Using Honeywell Temperature Controllers. Each Burner Has A Modulating Valve, Ignition Electrode, And Honeywell Primary Controller. Tube Used Is 6″ Diameter.

Simultaneously, Steam Can Be Introduced Through Stainless Steel Lances That Run The Width Of The Conveyor Belt. The Tube Burner Section Is Approximately 8′ In Overall Length. The Last Two Feet Of The Section Is Used As An Evacuation Chamber. This Chamber Is Used To Provide A Shiny Surface And Prevent Steam From Migrating Into The Direct Fired Oven Section. (2) Tube Fired Burners Are Used And Each Burner Is Individually Controlled As A Separate Zone. Each Burner Has A Capacity Of 750,000 Btu/hr in the steam system.

Turbulator Fans:

This System Utilizes Turbulator Fans To Provide A Faster Bake Time, Even Coloring, Moisture Retention, And Greater Sidewall Strength. The Fans Are Variable Speed And High Temperature Construction.

Tunnel Oven:

The Temperature Of Each Zone Is Controlled Using A Temperature Controller With Digital Readout. Each Burner Has Its Own Mixer, Gas Solenoid, Ignition Electrode, And Honeywell Spark Monitor Safety System. Each Individual Burner Can Be Manually Turned Off Without Affecting The Oven. Each Individual Burner Has A Maximum Heat Input Of 150,000 Btu/hr.

Pan Grouping Conveyor:

The Pan Grouping Conveyor Will An Effective Belt Width Of Approximately 30″And Utilizes KVP Plastic Belting (Or Equal) And Approximately 14′ Long

Oven Loader And Unloader:

The Equipment Uses Nosebar Construction Were Required To Transfer The Product In And Out Of The Oven. The Equipment Is Fabricated From Stainless Steel. The Loader And Unloader Utilizes Variable Frequency Drives To Synchronize Loading And Unloading Speeds With Equipment Upstream And Downstream.

Nominal Baking Chamber Dimensions: 40′ Long x 108″ Usable Width

Oven Loading Video CLICK HERE

Oven Unloading Video CLICK HERE

Specifications

There are no specifications currently available for this product

Product Videos

There are no videos currently available for this product

Warranty

Warranty text

Related Products

Looking for financing?

Pay for this item monthly with financing from our partner Alliance Funding Group

Apply Now!