Adamatic VDR Roll Line, 2010′

Shipping Weight TBD

Shipping times will vary.

Limited International Delivery Available.

Product Description

Full line that was at the IBIE show in 2010′ sold and put into production in 2011′ VERY nice line..

This Line Consists Of:

1) Adamatic/Glimek Hoist/Bowl/Hopper

1) Adamatic/Glimek Bulk Hopper

1) Adamatic VDR Divider Rounder

1) Adamatic Intermediate Proofer

1) Adamatic Bypass Conveyor

1) Adamatic Stamper Base

1) Adamatic Roll Stamper

1) 6 Row Tilting Infeed To Sheeter

1) Adamatic Sheeter

1) Adamatic Moulding Table

1) Moulding Table Extension

2) Moulding Systems

1) Adamatic Transfer/Timing Conveyor

1) Adamatic Automatic Reciprocating Panning Conveyor

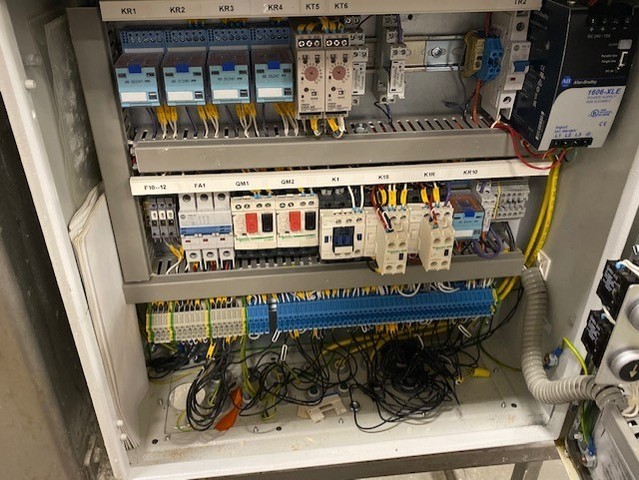

1) Standard Electrical Panel

Line setup with pistons and rounding drum, was making Hot’s Ham’s and Hoagies

for a 2oz to 3oz product.

More Pistons and Rounding drums can be purchased to achieve other sizes.

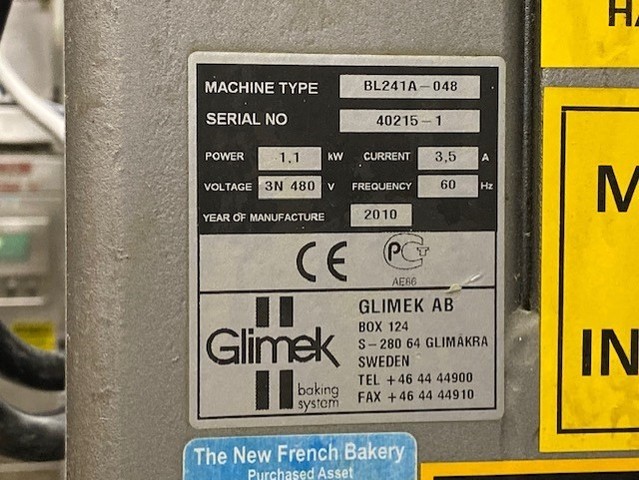

Adamatic/Glimek Hoist/Bowl/Hopper:

Model: BL241A-048

O.A. Dims: 4′-9″D x 5′-6″W x 13′-6″H

Air Requirements: 3/8″ Air Line @ 80 – 100 PSI

480V 3Ph 60Hz

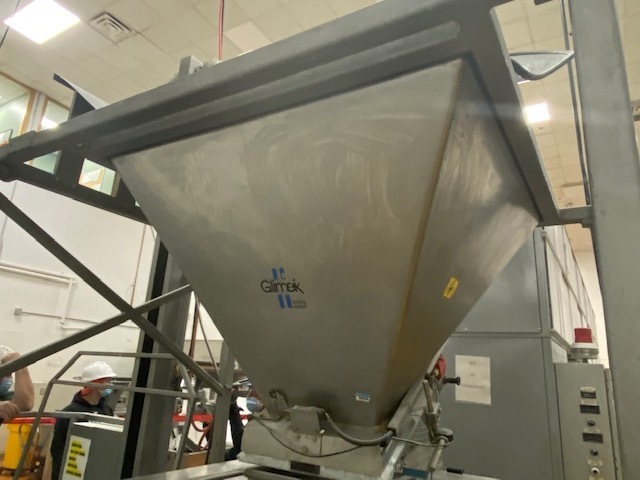

Adamatic/Glimek Bulk Hopper:

Capacity: 1000 lbs

Air Requirements: 70-100 PSI 3/8″ NPT

Teflon Coating Inside Hopper

Filter/Regulator Included

Safety Guard Between Gate And Divider/Rounder Hopper

Includes Floor Mounted Frame

Stainless Steel Construction

Adamatic VDR Divider Rounder:

4 – 6 Row Operation

Piston Diameter: 1-3/4″

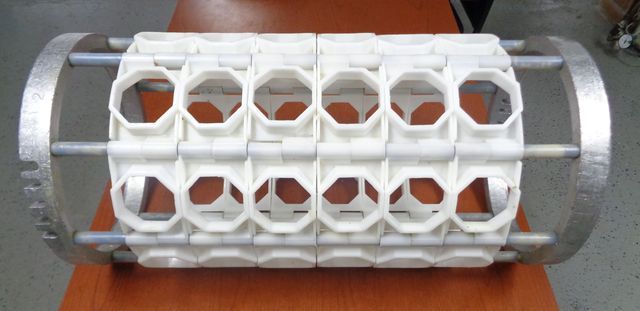

Rounding Drum:

13″ O.D.

11-3/8″ I.D.

Pocket Size: 2-1/2″ x 2-1/2″

6 Row

Drum Imprint: 0079253502

Additional Drums:

0079253503: 3 – 4 oz

0079253501: 1.25 – 2.0 oz

One Unmarked Drum: 67mm Diameter x 14mm Thick At the Hole.

Speed: Up To 50 Strokes Per Minute

Adjustable Finger Belt Discharge Conveyor

Straight Belt For Use With By-pass Conveyor

Fully Adjustable Hydraulic Main Piston

Variable Frequency Speed And Rounding Control

Stainless Steel Covers (Electrically Interlocked For Safety)

Digital Stroke Indicator

Central Drive Unit With Electric Clutch

Adjustable Height Flattening Roller

Simple Weight Adjustment

Flour Duster On Rear Belt

1.5 HP Rounding Motor

208/220V 60Hz 3Ph

Adamatic Intermediate Proofer:

Capacity: 8.64 Minute Proof At 10,000 Pieces Per Hour

Tray Capacity: 1 – 10 oz

Heavy Duty Roller Chain

Sliding Plexi Glass Inspection Windows

Stainless Steel Base Covers

High Impact Plastic Trays With Nylon Mesh Inserts

Knock Out Roller

Exhaust Fan/Humidistat Package

Catch Pan Under Proofer Base

Driven By Divider/Rounder

\Adamatic Bypass Conveyor:

Allows Round Rolls To Bypass Proofer To Allow For Steam Control

Adamatic Stamper Base:

Houses Drive Mechanism For Roll Stamper

Adamatic Roll Stamper:

6 Row Infeed Belts With Timing Gate Included

Flour Duster At Machine Entry

Individually Adjustable Discharge Belts

Sychronized With Proofer Discharge

Catch Pan Under Stamper

Driven By Divider Rounder

Tilting Infeed:

6 Across

Timing And Hold Back Gates

Adamatic Sheeter:

Model: SS31

31″ Belt

Pre Flattening Roller With Timing Gate

Two Sets Of Adjustable Non Stick Rollers

High Speed Coiling And Discharge Belt

1 HP Motor

208V 60Hz 3Ph

Adamatic Moulding Table:

Variable Speed Control

Pressure Plate Holding Brackets

Pnuematic Timing Device At Discharge

True Track Automatic Belt Tracking

Spinning Roller At Discharge

Alignment Chain After Plates

Flour Duster Mounted Over Alignment Chain

3 HP Motor

208/220V 60Hz 3Ph

Moulding Table Extension:

24″ Pre-Moulding Pressure Plate Assembly

Allows For Dual Moulding Board System For Extended Product Length

Adamatic Transfer/Timing Conveyor:

Independently Driven

One Timing Gate For Alignment Of Round Rolls And Hamburger Buns

Flattening Roller

Tubular Steel Frame

1.5 HP Motor 208/220V 60Hz 3Ph

Adamatic Automatic Reciprocating Panning Conveyor:

Model: PD-6

31″ Wide Retractable Belt

Variable Speed For Adjustable Spacing (Clustering Not Included)

Maximum Stroke 28″

Air Requirements: 70 To 100 PSI

Photocell Controlled

Hand Panning Shelf

1.5 HP Motor

208/220V 60Hz 3Ph

Standard Electrical Panel

Specifications

Product Videos

There are no videos currently available for this product

Warranty

Warranty text

Related Products

Looking for financing?

Pay for this item monthly with financing from our partner Alliance Funding Group

Apply Now!